bm2006: 16 RGB LEDs, 9V powered wearable unit that can run

standalone or with DMX

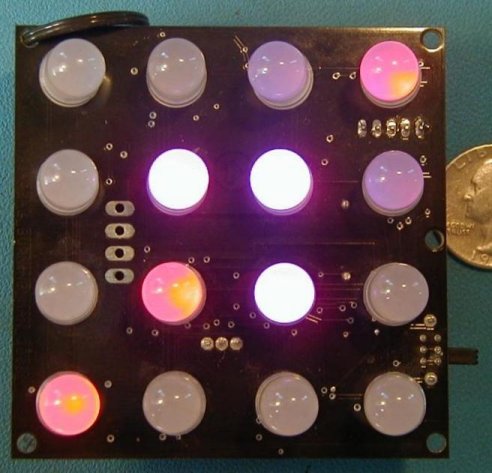

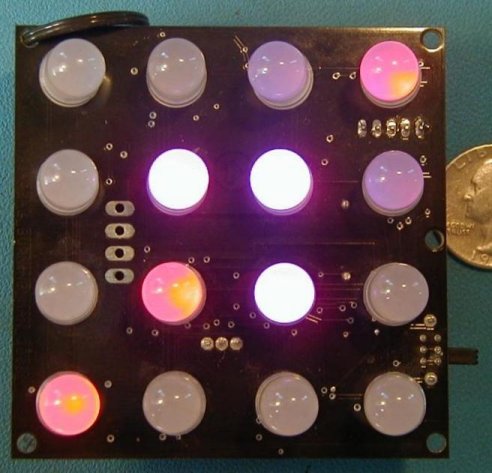

This web page documents a board with 16 RGB LEDs

Board size: 3.00 x 3.00 two-layer, with slick black soldermask

Project timeframe: August 2006

Client: Leo Villareal

Webpage created: May 20 2007

Top view:

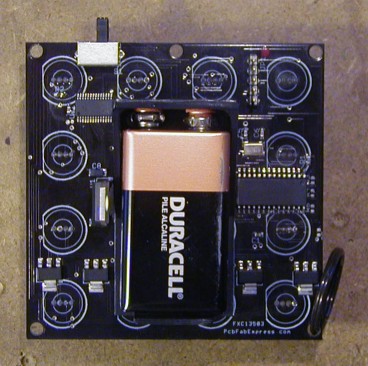

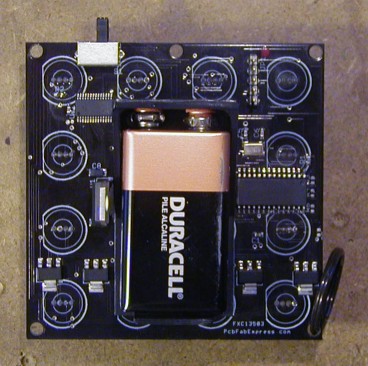

Bottom view:

bm2006 (i.e. the blinky for

Burningman 2006) is the latest and possibly final in the series of

wearable LED

blinkies for Leo Villareal / disorient.

(previous years: bm2005, bm2004). bm2006 is a grid of 16

10mm RGB LEDs, and is actually

two design variations on one board: standalone pattern synthesis, and

RS-485 controllable with either a custom protocol or DMX.

I did the "architectural" design of both the hardware and software -

describing the hardware design and writing the core software that runs

everything. Todd Polenberg did the hardware layout, handled the

manufacturing, and wrote the pattern synthesis part of the software

with my occasional consultation. The hardware layout is a bit of

a trick, while the board isn't particularly dense, the LEDs are 4-pin

through-hole and on a perfectly regular grid, and the electronics are

as SMT as possible and are all on the backside, placed between and

around the LED pin pads. Glad I made Todd do it. :)

The design has three major parts: a TI TLC5940 16 channel PWM LED

driver, four PFETs for a 4-way mux, and a PIC18F252 to run the

show. The PIC software is in C using the CCS C compiler.

The board can be built with a 9V holder (shown above) for wearing, or

with a 4-pin header for power/gnd/RS-485 and a standard 75176 8-pin

SOIC RS-485 transceiver.

The TLC5940

is a very handly little chip. While PWM can be done

in software (32 channels of 8-bit here),

this design needed 48 channels and to be able to drive the LEDs at

about 60mA - so the PIC can't sink the current thru a pin (current

limit for PIC i/o is a quite reasonable 25mA). By doing a 4-way

mux of the 16 LED driver chip we could achieve these goals with minimal

parts and hassle. Note: since the LED driver chip is 16 channels,

and we have 16 LEDs of 3 colors, why didn't we just do a 3-way

mux? Well, that was the original plan, but the layout was going

to be somewhere between arduous and impossible on a 2-layer

board. So for an extra 30c we did it 4-way.

There are some difficulties with the TI chip. For starters, it

doesn't just "auto run". It is 12-bit, and after sending it 4096

clocks, you have to toggle a pin to reset the PWM counter. This

is required, and is a serious design hassle. Additionally, it

seems in our usage anyway, that new PWM settings have to be loaded in

while the PWM clock is stopped. There may be something I'm doing

wrong, but considerable effort was spent with no luck. So this

means when doing multiplexing, where new PWM data is loaded each

multiplex step, that all the LEDs are off while the data is being

loaded. This makes the display more susceptible to flickering and

the overall output dimmer. However, for this design low power is

essential for battery operation for reasonable runtimes, so everything

is being run fairly dimly anyway. Flicker was not a problem at

all.

For dealing with the PWM counter: the PIC generates the PWM clock via

one of its hardware PWM generators running at maximum speed

(5Mhz). This goes to the TI chip and the input pin for one of the

PICs counters. When the counter hits 4096, the PWM generator is

turned off, new PWM data for the new mux phase is loaded into the TI

chip, the TI chip's PWM cycle is reset, the pfet for the mux step is

turned on, and then the PIC PWM hardware is activated again and repeat.

The RS-485 version hasn't been used much (at least not yet), but was

essential for making a 3x3 grid of these units, to form a DMX-enabled

prototype of this beast.

These also make excellent "taillights" for bicycle riding at night in

Oakland. Of course, being Oakland, you can't leave it on your

bike while you're at the bar... :)

Home